Plywood finishing line(movie 27sec.)

| Type of machine: | Plywood finishing and AI inspection line "Define" |

|---|---|

| Application: | Plywood side and board surface inspection device using AI. |

| Features: | Full automatic plywood finishing system from infeeding to sorting. Thid line is inclusive of 4-side sizing, thickness measuring, delamination detecting, and AI-assisted edge/surface inspection system. Those deffects difficult to be found by visual inspection are detectable by the advanced AI technology so as to achieve high precision quality control, high efficiency, and man-power / cost saving. |

Document Request> |

|

| Type of machine: | Model THC-THC Bundle Cut Sizing Line |

|---|---|

| Application: | High accurate plywood sizing by chain feed (one-by-one or bundle cut) |

| Features: | Chain feed type sizing line capable of book cut for any kind of plywood with high diagonal accuracy even for cross grain or film-ovelaid plywood without press mark and damage to the edges. Touch control panel of multi-language (Japanese / English / Korean / Chinese / Russian) switch-over screen allows immediate positionaing and feed speed setting at each section from auto infeeder to auto stacker including buffer conveyor. Saw blades can be replaced from the machine outside safely and easily. |

Document Request> |

|

| Type of machine: | Model CVC-THC Hybrid Plywood Sizing Equipment |

|---|---|

| Application: | Plywood sizing with high accuracy and efficiency even for cross grain plywood. |

| Features: | Hybrid sizing line of roll feed type 1st unit and chain feed type 2nd sizer assures you of high accuracy even for cross grain plywood.Touch control panel of multi-language (Japanese / English / Korean / Chinese / Russian) switch-over screen allows immediate positionaing and feed speed setting at each section. Saw blades can be replaced from the machine outside safely and easily. Ribbon cut device is available optionally to increase recovery. |

Document Request> |

|

| Type of machine: | Model CVC-CVC Automatic Positioning Sizing Equipment |

|---|---|

| Application: | High precision sizing processing of plywood |

| Features: | The high-precision positioning device makes it easy to change cutting dimensions, greatly increasing operating rates. Ribbon cutting is also available for effective use of ear wood. |

Document Request> |

|

| Type of machine: | Model 700 Series / 52 Series Wide Belt Sander |

|---|---|

| Application: | Plywood and board dimensioning and finishing |

| Features: | Conveyor belt feed type wide belt sander for plywood dimensioning and finishing. ● Sturdy frame construction assures vibrationless. heavy-duty operation at all times. ● High production realized because of multiple sanding heads and powerful conveyor belt feeding. ● Accurate thickness dimensioning guaranteed. ● Electric digital read-out for accurate adjustment of thickness opening and quick reference. ● Complete with safety devices. ● Constant passline device. (option) |

Document Request> |

|

| Type of machine: | Model TBO Combined Wide Belt Sander |

|---|---|

| Application: | Plywood, MDF, and Particleboard |

| Features: | Top and bottom head wide belt sander in one frame for thickness dimensioning and finishing of material panels, eliminating defects such as chip-out and knife mark apt to happen to knife planers. |

Document Request> |

|

| Type of machine: | Model BP-1300 Plywood Bending Machine |

|---|---|

| Application: | BP-1300 delaminates the weak adhesion spots of plywood by stress bending to conform to JPIC and other international standards. |

| Features: | Combination of this machine and Delamination Detecting Machine will enhance higher possibility of detecting the weak adhesion spots. This machine can be operated continuously as a part of Plywood Finishing Line without interruption of plywood production. |

Document Request> |

|

| Type of machine: | ZP524-430, with 4 sets of thickness sensor and 30-channel delamination sensors. Max. working width 60mm. ZPS521-430, economy type for max. 15mm thick (floorbase) |

|---|---|

| Application: | Plywood thickness measuring & delamination detecting |

| Features: | Nowadays, quality control of plywood is recognized as the most important process, especially thickness accuracy and internal defect detection so-called “PANKU” or delamination. ZP series enable this process automated with high reliablity by data transaction system to the personal computer for total quality control. Kikukawa original EXCEL software is provided for data processing. Touch control panel with multi-language screens and various function for easy operation. Delamination area can be shown on the screen. Defects identified by marking device and signal lights as well as shown on the screen. |

Document Request> |

|

| Type of machine: | Model PK Delamination Detecting System |

|---|---|

| Application: | Plywood delamination detecting |

| Features: | This system consists of Delamination Sensors, Fixing Frame and Independent Control Panel. Radiates the supersonic pulse to the materials in the infeed process, and then detects whether delamination is. It is possible to detect delamination of any materials such as plywood, MDF, and particle boards etc, without direct contact. |

Document Request> |

|

| Type of machine: | ZV/ZVS Series Thickness Measuring Machine with data transaction system to computer |

|---|---|

| Application: | Plywood thickness measuring |

| Features: | ZV524-4 : With 4 sets of thickness sensors for max 60mm thick. Model ZVS521-3 : Economy version of ZV, for max 15mm thick. Same features as ZP series without delamination detecting. |

Document Request> |

|

| Type of machine: | Model YGV Series Grading Machine for plywood |

|---|---|

| Application: | Classification by plywood bending test |

| Features: | In conformity with the contents of bending test prescribed in “JAS for Structural plywood”, this machine measures Young’s modulus of bending strength of plywood in continuous feed, and grades plywood into first class, second class and out of class. |

Document Request> |

|

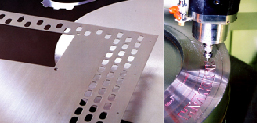

| Type of machine: | Model T852-2F Core Veneer Grinder "ATOM" [PAT.] |

|---|---|

| Application: | Core veneer thickness dimensioning. Overlap repair for thin plywood. |

| Features: | Solution to uneven core veneer thickness, overlapped veneer repairing, delamination of weak veneer lamination, low recovery, etc. ● For thickness dimensioning of 1-ply, 3-ply or 5-ply core veneer: However twisted the veneer is, special hold-down device allows thicker part only to be dimensioned. ● For repair work of thin plywood: Automating troublesome manual repair job of overlapped portions efficiently, and save man-power remarkably. ● Long lifetime and cost saving of specially designed grinding head: Consumable abrasive belts are not used. Provided with automatic cleaning device to assure continuous operation. ● Also effective for cross grain veneers ● Max. working width 1,270mm, min. working length 30mm. |

Document Request> |

|

| Type of machine: | Model ZX-60/ZX-100 Dry Abrasive Cleaning System |

|---|---|

| Application: | Recycling used abrasive belts by dry cleaning |

| Features: | ZX using a sand-blasting technique will revolutionize your sanding operation by recycling your used abrasive belts for saving your money and improving finish quality! ZX system is easy to operate and nearly maintenance free with quick payback! Cleaning media is no hazardous, non-flammable and recycled itself. Because of dry cleaning system, no drying time and fewer belts to purchase, inventory and dispose of. ZX-60 has the capability of cleaning belts up to 60”(1520mm) wide, any length. ZX-80 up to 2000mm wide and ZX-100 up to 2540mm. |

Document Request> |

|

| Type of machine: | Model WG48 Multiple Sizer |

|---|---|

| Application: | Straight and small cutting of thick plywood, LVL, etc. |

| Features: | 1300mm wide heavy-duty multiple sizer of dip chain feed, assuring high accuracy in cutting plywood, LVL, MDF, hardboard, etc. |

Document Request> |

|